Airgun Regulator Basics

by Joe Korick

click the ad to visit this advertiser, View All Advertisers On This Page

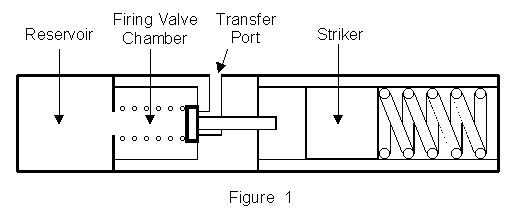

In order to understand the regulator as it applies to the precharged pneumatic airgun we must first look at a non regulated version. Figure 1 is an illustration of the basic non regulated airgun.

When the gun is cocked the striker is pulled back a certain distance before the trigger sear engages. This distance is called the Stroke. When the trigger is pulled the striker is released and travels forward striking the valve stem of the Firing valve lifting it off its seat allowing air to flow past through the Transfer port and into the barrel. The length of time the valve remains open is referred to as Valve duration and is measured in thousandths of a second. As the reservoir pressure decreases the valve duration increases due to less resistance of air pressure on the firing valve. As the valve duration increases a larger volume of air at a lower pressure is allowed to pass. The result is a rise in pellet velocity. Figure 2 shows the typical velocity verses number of shots curve of a non regulated gun.

Looking at the curve you can see an area where the curve is somewhat consistent. This is called the heart of the fill. Most people will find this area and shoot their gun here for the greatest accuracy. To find this area the gun is filled to full pressure and shot over a chronograph. The shots are counted, velocities recorded and the graph plotted. The pressure at the end of the test is recorded and subtracted from that of the beginning. This number is divided by the number of shots and the result is approximately the amount of pressure per shot that the reservoir diminishes. The gun will now be charged to the pressure where the graph starts to flatten and shot to where the graph starts to drop off. In order to extend this plateau into the higher supply pressures and maintain greater shot to shot consistency a regulator is used.

What is a regulator?

Regulators come in different shapes and sizes. Designs vary from manufacturer to manufacturer but the end result is the same. A regulator is simply a valve. Probably one of the simplest regulating devises is the firing valve used in the Titan and Falcon line of guns. The area around the plastic firing valve has a set clearance that limits the air being allowed to pass. In this system the gun remains somewhat constant over a range of several hundred PSI. The conclusion drawn from this is that it isn't a function of pressure propelling the pellet as much as a given volume of air to get the job done. The job of the regulator is to maintain a constant output pressure while the input pressure varies. In the airgun the regulator does not regulate the flow of the air as much as it regulates the pressure of the firing valve chamber. Some regulators have a very slow recovery rate, others are almost instantaneous. As discussed earlier pressure alone is not enough to do the entire job, there must also be enough volume at this pressure to propel the pellet at the desired velocity. Therefore an efficient regulator system must also include a secondary chamber of sufficient size for the job at hand.

How does a regulator work?

Most of the airgun regulator manufacturers do not want their secrets to get out. The reality of the issue is that their designs are based on SCUBA equipment with small modifications to suit the needs of the airgun. In an attempt not to give away any one design and to prove a point the illustration in Figure 3 is taken from a 1975 SCUBA divers training manual which pre dates the precharge pneumatic air rifle of today. This regulator design is called a " Balanced flow-through piston valve".

The air enters the regulator from the reservoir, travels through the piston and into the firing valve chamber. As the pressure increases so does the force on the large end of the piston. As the force increases on the piston the spring behind the piston begins to compress. This process continues until the shaft of the piston contacts the teflon seat and shuts the flow of air off. When the shot is fired the air pressure in the firing valve chamber drops and the spring lifts the piston off its seat allowing high pressure air to flow into the valve chamber once again and the cycle is repeated.

The pressure in the firing valve chamber is determined by the size of the piston head and the strength of the spring. These dimensions will vary between manufactures, among all the airgun regulators available today none has the same dimensions as another. There are, however, several regulators available that use this basic design.

Typically you would want the regulator to be set at a pressure that is in the middle of the "Heart of the fill" so that small variances in gun operation would have little or no effect on pellet velocity. This is not always the case. Some people want to shoot at very high velocities with heavy pellets and push the gun to its limits. Because the gun is operating so close to its limits, alterations are necessary. These might include Lengthening the stroke, larger transfer ports, increasing striker spring tension, changing the firing valve and or valve spring are all options that can greatly affect gun operation. The precharge Pneumatic airgun is a DYNAMIC SYSTEM meaning that all these factors are in a state of balance and each has an effect on one another. Unless someone is completely familiar with these principals, adjustments and modifications should be left to the airgunsmith.

Regulator Pros and Cons

Regulators extend the amount of shots per fill and bring the shot to shot consistency closer. For the serious competitor whether it be field target, bench rest, silhouette or 10 meter shooting. Regulators are a part of basic equipment requirements.

The down side of regulators is that they are mechanical devices and consequently can fail. Regulators depend heavily on rubber O-Rings for seals. With time and use the rubber can dry out and crack. They are also subject to wear, as the valve moves back and forth from shot to shot the o-rings are rubbing the walls of the regulator body. It's really just a matter of time or number of shots before some maintenance is required. This could leave a shooter in a bad situation if it happened at a match. If a shooter shoots a lot then a yearly check up should be considered. Fortunately o-rings are not very expensive and primarily represent the majority of repairs required.

Back to General Airgun Information

Back to American Airgun Home

Top of Page

click the ad to visit this advertiser, View All Advertisers On This Page

© Copyright 2006 by Brad Troyer & American Airguns